Cooling Tower : What is Cooling Tower, Types & Industrial Applications

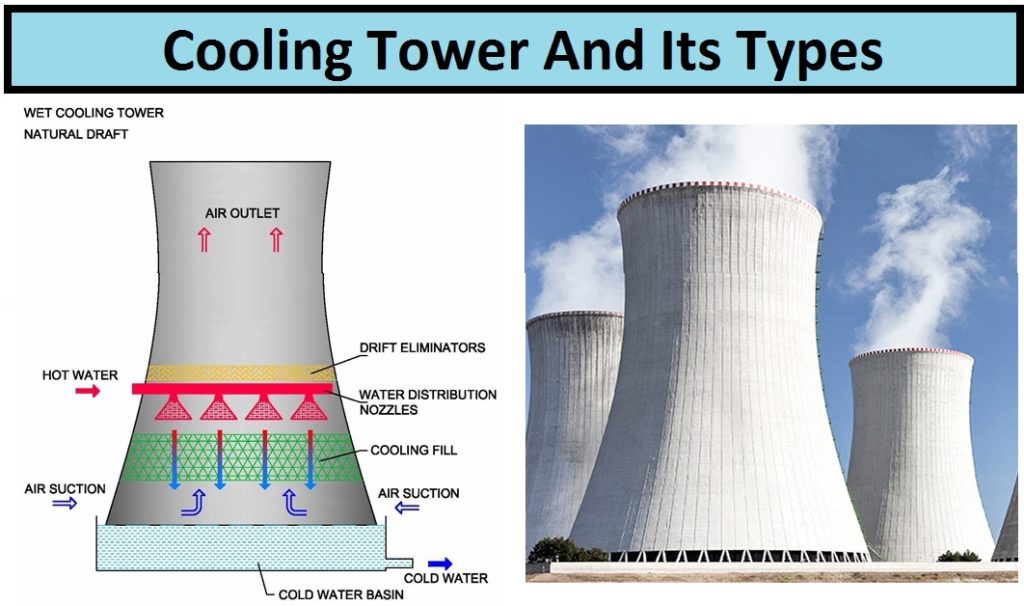

A cooling tower is a device which is used to extract excess heat from the process water stream and rejects this excess heat to the atmosphere. In industry a large amount of heat is generated continuously which is required in various processes. Cooling tower technology is the prime way of rejecting this large amount of heat (or waste heat after processes) to the atmosphere by means of heat exchange process between Air and Hot water stream.

There is a heat exchange takes place between hot water stream and dry air generally termed as “Evaporative Cooling ” in which a small portion of the water gets cooled to evaporate into a moving air stream, which provides a significant cooling to the rest of the stream or simply say cooling the working fluid to near wet bulb temperature using evaporation.In case of closed circuit dry cooling towers cooling of the working fluid takes place up to dry bulb temperature of dry air.

The size of the cooling towers may vary from small roof-top units to very large hyperboloid structures (can be up to 200 metres (660 ft) tall and 100 metres (330 ft) in diameter), or in rectangular structures (can be over 40 metres (130 ft) tall and 80 metres (260 ft) long).

Types of Cooling tower

a) On the basis of Heat Transfer Methods Cooling Towers are classified as:

- Dry cooling towers

- Wet cooling towers (or open circuit cooling towers)

- Fluid coolers (or closed circuit cooling towers)

b) On the basis of Air Flow Generation Methods Cooling Towers are classified as:

- Natural Draft

- Mechanical Draft ( Induced / Forced Draft )

- Fan assisted natural draft

Dry cooling towers: In this type of cooling tower the transfer of heat takes place through a surface which separates the working fluid from ambient air, such as in a tube to air heat exchanger, utilizing convective heat transfer. They do not use evaporation technique, so the consumption of makeup water is very less. No liquid is used for cooling technique.

Wet Cooling Tower : It is also termed as open circuit cooling towers. The working principle of wet cooling towers is based on evaporative cooling technique. Here the working fluid or the fluid used for heat exchange and the fluid that is actually evaporating is the same i.e. water.

Fluid Coolers : It is also known as Close circuit cooling tower. In this case working fluid passes through a tube bundle upon which clean water is sprayed and a fan-induced draft applied. Here the extent of cooling obtained is much closer to that of a wet cooling tower.

Natural Draft Cooling Tower : It is a large tall Hyperboloid type cooling tower having wide-mouthed. Hyperboloid shape aids in accelerating the upward convective air flow, which improves cooling efficiency. Natural draught tower utilize the principle of buoyancy to achieve the desired effect. Since the warm and moisture-laden air having less density so move upwards naturally towards the dry and cooler air outside the tower. Thus due to this exchange of heat cooling takes place. This type of tower is very much suitable for large area and heavy load.

Mechanical Draft Cooling Tower

a) Induced Draft Cooling Tower : In this type of mechanical cooling tower a powerful fan is installed unit at the top of the tower. Due to this when this fan is get on produces low entering and high exiting air velocities just like a powerful exhaust fan. The presence of this powerful exhaust fan eliminates the risk of re-circulation.

b) Forced Draft Cooling Tower : In this type of cooling tower very high velocity fan is installed at the bottom of the tower. Due to this when this fan is get on produces high entering velocity to the air compare to that of exit velocity. In this type of cooling tower not only cooling takes place but also rise in the pressure of the system takes place. This is applicable where cooling plus pressuring both are required.The presence of this powerful fan installed at bottom eliminates the risk of re-circulation.

References : Wikipedia; Engineering insider