What does Human-Machine Interface (HMI) mean?

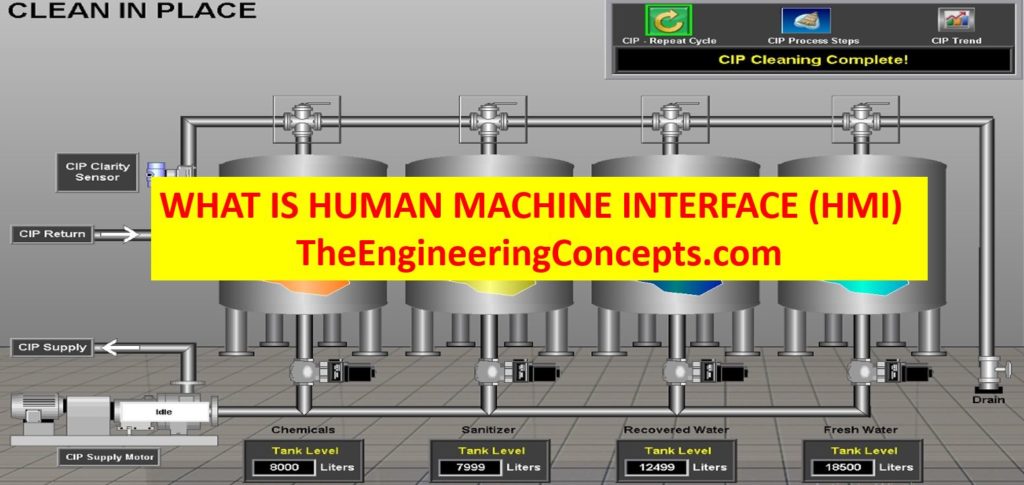

A Human-Machine Interface (HMI) is basically a user friendly interface or dashboard which helps in connecting a person to the machine, system, or device in a very smart way. This HMI is applicable for any screen where there is a interaction going between user and machine. HMI is most frequently used in industrial process.

In another way HMI can be defined as ;

Human-machine interface (HMI) is a compilation of certain devices that are capable of handling human-machine interactions. The interface consists of hardware and software that allow user inputs to be translated as signals for machines that, in turn, provide the required result to the user. Human-machine interface technology is been used in different industries like electronics, entertainment, chemical, pharmaceuticals, military, medical, etc. By the help of Human-machine interfaces user/humans can also be able to operate / handle complex technological systems.

In another word Human-machine interface (HMI) can be termed as man-machine interface (MMI) or, computer-human interface or, human-computer interface.

In industrial process / activity, HMIs can be used to:

- Visually display data required

- helps operator in tracking production time, trends, and tags

- Oversee KPIs

- helps in monitoring machine inputs and outputs

- helps in regulating variable parameters

- And more

Human-Machine Interface (HMI)

In case of HMI, the interactions takes place is basically of two types, i.e.,

- Human to Machine &

- Machine to Human

Now a days HMI technology is frequently present everywhere, this interface involves keyboard(helps in user to give command / inputs), motion sensors, similar peripheral devices and many other information exchnging devices, also includes sound,heat and many others components considered as a part of HMI.

The basis of building HMIs mainly depends on the understanding of human physical, behavioral and mental capabilities. Apart from enhancing the user experience and efficiency, HMIs can provide unique opportunities for applications, learning and recreation. In fact, HMI helps in the rapid acquisition of skills for users. A good HMI is able to provide realistic and natural interactions with external devices.

The advantages provided by incorporating HMIs include error reduction, increased system and user efficiency, improved reliability and maintainability, increased user acceptance and user comfort, reduction in training and skill requirements, reduction in physical or mental stress for users, reduction in task saturation, increased economy of production and productivity, etc.

Touchscreens and membrane switches also comes in the list of examples of HMIs. HMI technology is also used widely in virtual and flat displays, pattern recognition, Internet and personal computer access, data input for electronic devices, and information fusion.

Professional bodies like GEIA and ISO provide standards and guidelines applicable for human-machine interface technology.

Who Uses HMI?

Now a days HMI technology is used frequently approx by almost all industry / organizations, helps organization in reducing man power too.

Industries using HMI include:

|

|

|

Similar Articles :

What is the Difference Between HMI and SCADA?

What is SCADA ? How does SCADA Works?

What is Programmable Logic Controller / PLC ?

What is Distributed Control Systems (DCS) ?

ImageSource : Kasa Controls ; Google Sites ; Machine Design ; Sielco Sistemi

ArticleSource : inductive automatio