What is Boiler | Components & Application of Boiler System

Definition : What is Boiler?

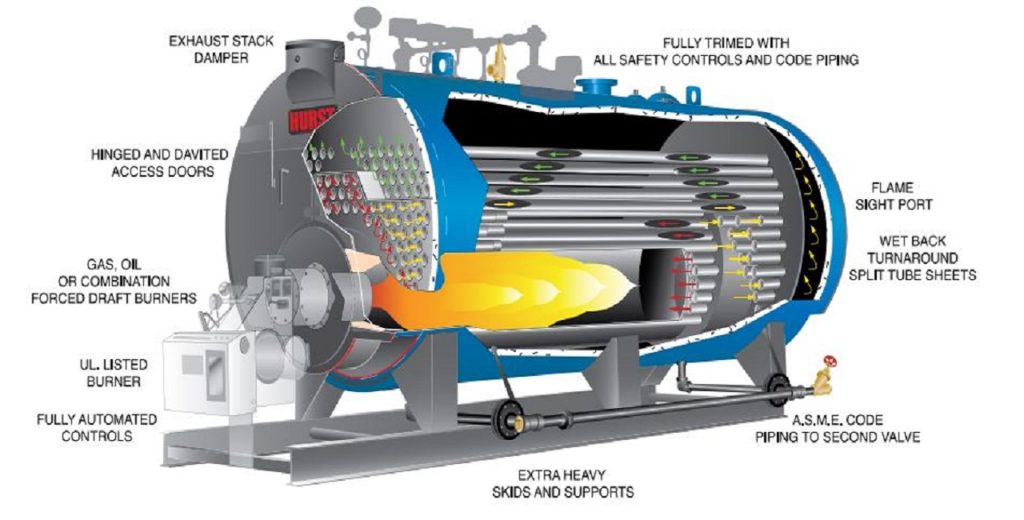

A boiler is defined as “A closed vessel in which water or other liquid is heated, steam or vapor is generated, steam is superheated, or any combination thereof, under pressure or vacuum, for use external to itself, by the direct application of energy from the combustion of fuels, from electricity or nuclear energy ”.

A Brief Introduction :

- Boiler is a main working component of thermal power plants.

- Water is useful and cheap medium for transferring heat to a process.

- When water is boiled into steam its volume increases about 1,600 times, producing a force that is almost as explosive as gunpowder.

- This causes the boiler to be extremely dangerous equipment and should be treated carefully.

- Liquid when heated up to the gaseous state this process is called evaporation.

- The heating surface is any part of the boiler; hot gases of combustion are on one side and water on the other. Any part of the boiler metal that actually contributes to making steam is heating surface.

- The amount of heating surface of a boiler is expressed in square meters.

- The larger the heating surface a boiler has, the more efficient it becomes.

Fuel Used in Boiler

The list of major fuels which are employed in boiler systems is given below:

- Natural Gas

- Propane

- Oil

- Electricity

- Solids Fuels like Coal & Wood

- Renewable Energy

Solid Boiler fuels: Major solid fuels used for burning in a boiler include coal and wood. They were the only fuel sources available for use in boiler systems prior to the emergence of heating fuel oil. These are the cheapest means of boiler fuels which are getting exhausted day by day due to uncontrolled use.

- Wood

- Coal

- Briquettes

- Pet Coke

- Rice Husk

Liquid Boiler Fuels :

- LDO

- Furnace oil

LPG (Liquid Petroleum Gas)

In practice, LPG is mainly used in applications where the availability of natural gas is either very limited or costly. LPG works as a boiler fuel in similar manner as natural gas. However, the boiler in use must be capable of conversion features so that it could be made compatible with LPG.

Major Gaseous Boiler Fuels are as :

- LPG

- LNG

- PNG can be used to carry out the combustion for the specific purpose.

Components of Boiler System

There are 3 backbone components of any boiler system:

1. Boiler Feed Water System

Water that converts into steam by steam boiler system called Feed water & system that regulates feed water called Feed water system.

There are two types of feed water systems in boilers:

- Open feed System

- Closed feed system

There are two main sources of feed water:

- Condensed steam returned from the processes

- Raw water arranged from outside the boiler plant processes ( Called: Makeup Water)

2. Boiler Steam System

Steam System is kind of main controlling system of boiler process. Steam Systems are responsible to collect & control all generated steam in the process.

Steam systems send steam generated in the process to the point of use through pipes ( piping system). Throughout the process, steam pressure is controlled and regulated with the help of boiler system parts such as valves, steam pressure gauges etc.

3. Boiler Fuel System

Fueling is the heart of boiler process & fuel system consists of all the necessary components and equipment to feed fuel to generate required heat. The equipment required in the fuel system depends on the type of fuel used in the system.

Also Read: Control Loop

Boiler Applications

The Boilers have a very a wide application in different industries such as

Food Industry

Food must often be heated or boiled during processing. Thus this industrial sector obviously needs plenty of thermal energy. However, some steam applications are still stunning; a good example is potato processing.

Breweries

Most people know that a good and tasty beer consists of hops, malt and water. However, before enjoying the beer there is a complex production process. Malt has to be ground coarsely and mixed with water. The brewer calls this mashing. The mash must be heated to various temperatures in two to four hours. Steam generated with the steam boiler is normally used as a heat carrier. Subsequently, hops are added and the mixture has to cool down. Then yeast is added and triggers the fermentation so that the beer gets the desired effect. Again after bottles or barrels have been emptied they are normally returned to the brewery. Of course the breweries first have to clean them before they can be refilled. For this process steam is again required to heat up the water needed for cleaning.

Building materials industry

Large amounts of steam are also necessary for the production of molded bricks. The basic materials like sand, lime, water, etc. are mixed and pressed to relatively loose stone compounds. Subsequently, the stones are transported to a huge pressure vessel (autoclave) which is then closed and steam is injected. The stones have to harden at a temperature of approximately 200 °C and a pressure of about 16 bar for a certain period of time and can then be withdrawn as finished stones.

Sewer pipe rehabilitation

What to do if there is a drain leakage? This problem can either be solved by means of excavation works at the underground pipes and renewal of the sewage pipe systems or with rehabilitation tubes. These tubes are overdimensioned hoses that are inserted in the pipes without excavation work and then inflated with steam. The plastic hose attaches itself to the sewage pipe under application of pressure and temperature and the pipe can continue to be used for many years.

many other Industries such as :

- Power Sector

- Textiles

- Plywood

- Food Processing Industry

- FMCG

- Sugar Plants

- Thermal Power Plants

Boilers Source: Thermodyne Industrial Boiler Products

Industrial Steam Boiler Manufacturer

Thermodyne design, manufacture and supply ISO 9001:2008 certified steam boilers, for such processes and several others too.

Thermodyne Engineering Systems can help you by saving up to 30% of the fuel cost by providing high-efficiency boilers, the Energy consultancy, and customized heating solutions.

Fuel saving is not only important for margins, but also for the environment. Industry can count on Thermodyne because we believe in Enhancing Energy Efficiency.

Also Read:

Venturi Flow Meter

Pitot Tube

Coriolis Mass Flow Meter

Design of Centrifugal Pump

Valve & Its Types

Cavitation

Piping and Instrumentation Diagram – P&ID

Refrence Books :

Practical Boiler Operation Engineering and Power Plant

Boiler Operators Handbook

Boiler Operators Handbook