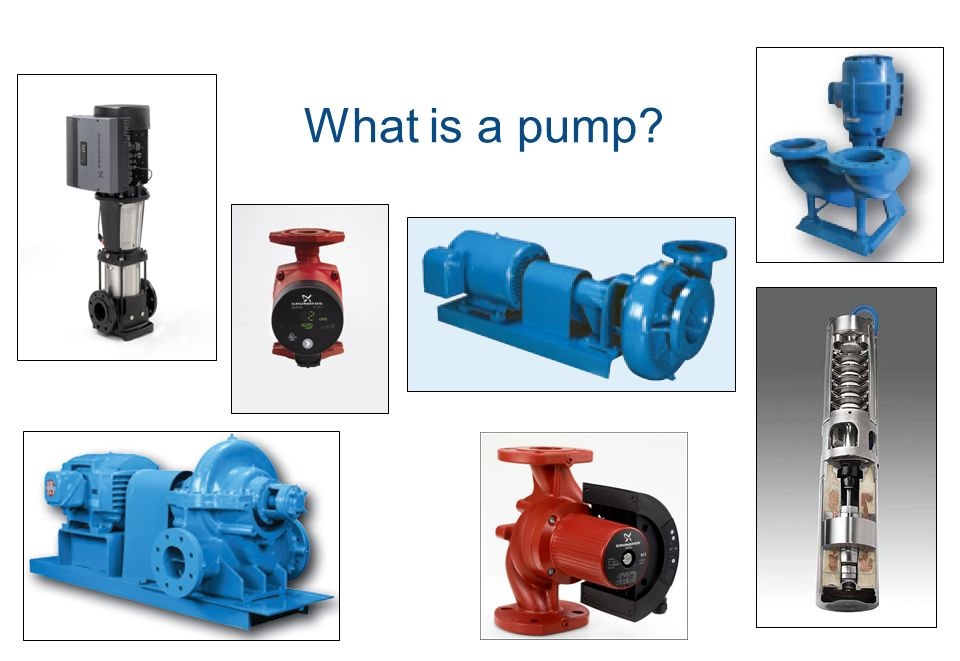

What is a Pump ?

A Pump is a mechanical device used to move fluids such as liquids , gases or slurries.

It increases the additional energy of the Fluid.

The additional energy can be used to increase –

- Velocity (flow rate )

- Pressure

- Elevation

Classification Of Pump

Pumps are broadly categoraized as :

- Positive Displacement Pumps : A positive displacement pump makes a fluid move by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe.

Positive displacement pumps, which lift a given volume for each cycle of operation, can be divided into two main classes, reciprocating and rotary. Reciprocating pumps include piston, plunger, and diaphragm types; rotary pumps include gear, lobe, screw, vane, and cam pumps.

- Dynamic Pumps : Rotodynamic pumps (or dynamic pumps) are a type of velocity pump in which kinetic energy is added to the fluid by increasing the flow velocity. This increase in energy is converted to a gain in potential energy (pressure) when the velocity is reduced prior to or as the flow exits the pump into the discharge pipe.

Centrifugal pumps are the most common type of pump used in industry. There are three basic sub-types of centrifugal pumps:

- Axial Flow Pumps are high flow, low pressure pumps which lift fluid in a direction parallel to the impeller shaft.

- Mixed Flow Pumps are medium flow, medium pressure pumps which push fluid out away from the pump shaft at an angle greater than 90°.

- Radial Flow Pumps are high pressure, low flow pumps which accelerate fluid along the impeller blades perpendicular to the shaft.

Working of Centrifugal Pumps

Impeller – The Heart of Centrifugal Pumps

Centrifugal pumps are used to induce flow or raise pressure of a liquid. Its working is simple. At the heart of the system lies impeller. It has a series of curved vanes fitted inside the shroud plates. The impeller is always immersed in the water. When the impeller is made to rotate, it makes the fluid surrounding it also rotate. This imparts centrifugal force to the water particles, and water moves radially out.

Diffuser :

A diffuser is actually a series of vanes surrounding the impeller which accepts the discharge of liquid from the impeller. It efficiently reduces the velocity and, in the case of a multistage pump, directs this lower velocity fluid into vaned return channels which guide the liquid to the inlet or eye of the next stage impeller.

Volutes :

Volutes are designed to capture the velocity of liquid as it enters the outermost diameter of an impeller and convert the velocity of the liquid into pressure.

The Key Performance Parameters of A Centrifugal Pump

-

- Head

The concept of head is used for Newtonian fluids or true fluids such as water and petrol like non-viscous liquids. Hence, the term head is basically the measurement of kinetic energy created by the pump. It measures the height of a liquid column which the pump creates. Head measures energy of the centrifugal pump . The end users can describe the performance of a pump on any Newtonian fluid, be it as heavy as sulphuric acid or as light as gasoline, by using head. Here, head relates to the velocity gained by the liquid while moving through the pump.

-

- Friction Head (hf):

In the pipe and fittings the head required to deal with the resistance to flow is known as friction head. Friction head depends on the following factors:

-

-

- size of pipe

- condition of pipe

- type of pipe

- the number of pipe fittings

- type of fittings

- flow rate

- nature of the liquid

- Velocity Head (hv):

-

The energy created in a liquid due to its motion at some velocity say V is called velocity head. This factor is usually insignificant and is mostly ignored in high-head systems. However, in low-head systems, it can be a large factor and must be considered.

3. Pressure Head:

This factor is considered when a pumping system begins from or empties into a storage tank that is under some pressure. Here atmospheric pressure is not taken into consideration. The pressure in converted to feet of liquid.

When we combine different types of head, it sums up to the total system head at a particular rate of flow

NPSH (Net Positive Suction Head) :

The margin of pressure over vapor pressure, at the pump suction nozzle, is Net Positive Suction Head (NPSH).

or, The difference between inlet pressure and the lowest pressure level inside the pump is called NPSH (Net Positive Suction Head). NPSH is therefore an expression of the pressure loss that takes place inside the first part of the pump housing.

In equation form:

NPSH = Ps ‑ Pvap

Where:

NPSH = NPSH available from the system, at the pump inlet, with the pump running

Ps = Stagnation suction pressure, at the pump inlet, with the pump running

NPSH will cause the lowest pressure inside the pump to decrease below the evaporation pressure of the pumped liquid, if the inlet pressure is too low. Consequentially, cavitation occurs in the pump, causing noise and leading to breakdowns.

Advantages Of Centrifugal Pump are :

Disadvantages :

ImageSource : allpumps; Alibaba.com; Mechanicallyinfo.com; SlideShare; nuclear-power.net;