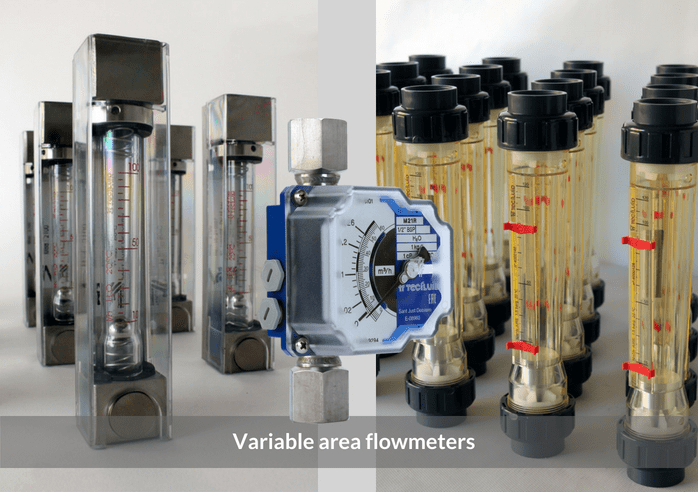

Types of Variable Area Flow Meters

Variable Area Flow Meters

The variable area flow meter is a reverse differential pressure meter use to accurately measure the flow rate of liquid and gases.In case of orifice meter/ venturi-meter, there is a fixed aperture and flow is indicated by a drop in differential pressure. In area meter, there is a variable orifice and the pressure drop is relatively constant. Thus, in the area meter, flow is indicated as a function of the area of the annular opening through which the fluid must pass. This area is generally readout as the position of a float or obstruction in the orifice.

The effective annular area in area meter is nearly proportional to height of the float, plummet or piston, in the body and relationship between the height of float and flow rate is approximately linear one with linear flow curve as well as scale graduations.

Measuring tubes of different materials

The measuring tube of variable area flowmeters can be made of different materials:

-

Plastic tube. This type of material allows to read directly the flow if the fluid is transparent, otherwise we could not see the float and therefore we could not do the reading.

-

Glass tube. Like the plastic tubes, it is possible to directly read the flow rate in case the fluid is transparent.

-

Metal tube. In this type of tube it is not possible to make a direct visual reading of the flow so it is necessary that the position of the float is transmitted by magnetic coupling to a scale that is inside an indicator box mounted together with the measurement tube.

The material of the rest of components; wetted parts, float, gaskets is also manufactured in different materials depending on the chemical compatibility with the fluid to be measured and the process conditions.

Types of Variable Area Flow Meters

Area meters are of two general types :

- Rotameters and

- Piston type meter.

Rotameters

Rotameters are the most widely used type of variable-area (VA) flowmeter. In these devices, the falling and rising action of a float in a tapered tube provides a measure of flow rate . Rotameters are known as gravity-type flowmeters because they are based on the opposition between the downward force of gravity and the upward force of the flowing fluid. When the flow is constant, the float stays in one position that can be related to the volumetric flow rate. That position is indicated on a graduated scale. Note that to keep the full force of gravity in effect, this dynamic balancing act requires a vertical measuring tube.

In this meter, a weighted float or plummet contained in an upright tapered tube, is lifted to the position of equilibrium between the downward force of the plummet and the upward force of the fluid in addition to the buoyancy effect of the fluid flowing past the float through the annular orifice. The flow rate can be read by observing the position of the float.

Construction & Working Principle

The term rotameter derives from early versions of the floats, which had slots to help stabilize and center them and which caused them to rotate. Today’s floats take a variety of shapes, including a spherical configuration used primarily in purgemeters (which will be discussed later on). The materials of construction include stainless steel, glass, metal, and plastic.

The tapered tube’s gradually increasing diameter provides a related increase in the annular area around the float, and is designed in accordance with the basic equation for volumetric flow rate:

| (1) |

where:

| Q | = volumetric flow rate, e.g., gallons per minute |

| k | = a constant |

| A | = annular area between the float and the tube wall |

| g | = force of gravity |

| h | = pressure drop (head) across the float |

With h being constant in a VA (variable area) meter, we have A as a direct function of flow rate Q. Thus, the rotameter designer can determine the tube taper so that the height of the float in the tube is a measure of flow rate.

Piston Type Meter

In this meter, a piston is accurately fitted inside a sleeve and is lifted by fluid pressure until sufficient post area in the sleeve is uncovered to permit the passage of the flow. The flow is indicated by the position of the piston.

Monitor air flowrates to determine optimum performance, flow regulator settings, or pneumatic system performance. Ideally for use in mobile or industrial pneumatic systems as well as air power operated hand tool systems.

Fig. shows the types of Variable area flow meter (a) Rotameter and (b) Piston Type meter.

Performance Characteristics

1. Linearity

The flow rate (volume) through a variable area meter is essentially proportional to the area and, as a result, most of these meters have essentially equal-scale increments. A typical indicating rotameters scale is non linear by about 5%.

2. Differential

An important characteristic of the variable area meter is that the pressure loss across the float is a constant. The overall differential across the meter will increase at higher flow rates because of friction losses through the fittings.

3. Accuracy

The most common accuracy is ±2% of full scale reading. This increases considerably with individual calibration and scale length. Repeatability is excellent.

4. Capacity

Variable area flow meters are the most commonly used means for measuring low-flow rates. Full scale capacities range from 0.5 cm3/min of water and 30 std cm3/min of air in the smallest units to over 1200 litres/min of water and 1700 m3/h of air in 8 cm height meters.

5. Minimum Piping Requirement

An area meter usually can be installed without regard to the fittings or lengths of straight pipe proceedings or following the meter.

6. Corrosive or Difficult to handle liquid

These can often be handled successfully in an area meter. They include such materials as oil, tar, refrigerants, sulphuric acid, black liquor, beverages, aqua regia and molten sulphur. In general, if the nature of the fluid does not permit the use of a conventional differential pressure type meter because the fluid is dirty, viscous or corrosive, certain area meters have an advantage over other types of meters.

7. Pressure Drop

By placing very light floats in over sized meters, flow rates can be handled with a combination of very low pressure loss (often 2.5 cm of water column or less) and 10 : 1 flow range.

Refrences : TecFluid Wikipedia