What is an Orifice Meter?

Introduction

An Orifice Meter is basically a type of flow meter which is used to measure the rate of flow fluids (mainly Liquids or Gases), using the Differential Pressure Measurement principle.

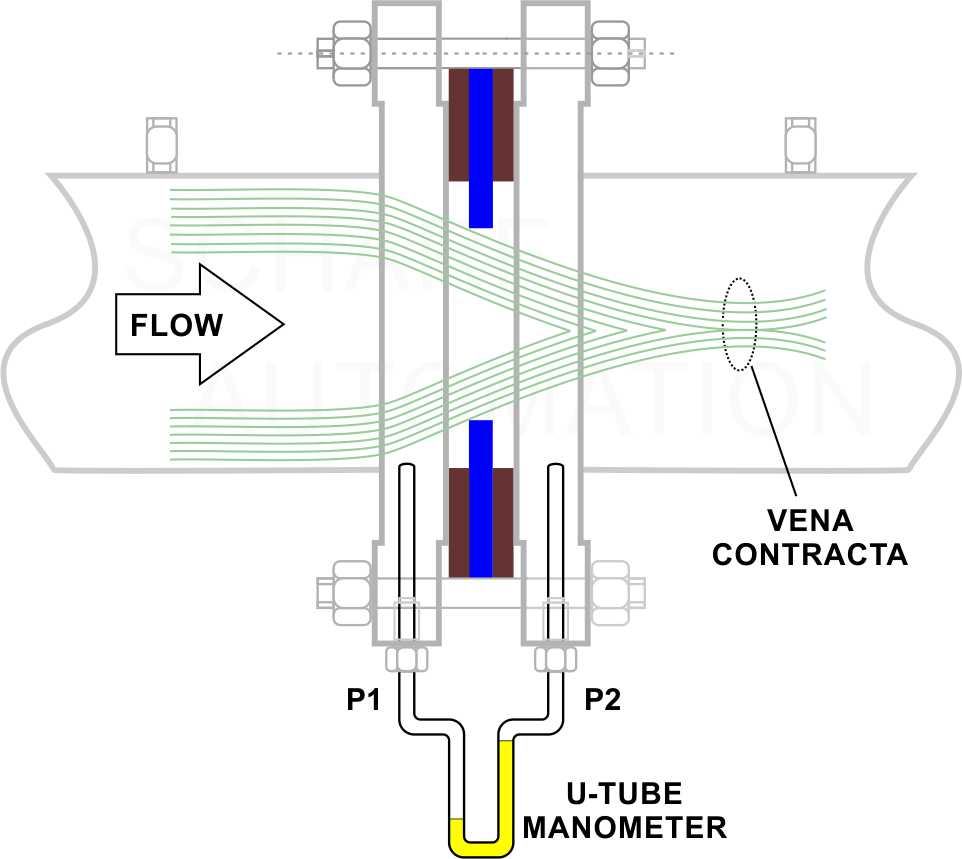

There is basically an Orifice Plate installed in the orificemeter which provides obstruction to the fluid flow. Here, the streamline contracts because of the area contraction due to orifice which is placed between the pipe by flange.

There is a vena -contacta considered as minimum area -cross section.

A differential pressure is developed across the Orifice Plate which is directly proportion to the flow-rate of the liquid or gas.

Principle:

When a liquid / gas, whose flow-rate is to be determined, is passed through an Orifice Meter, there is a drop in the pressure between the Inlet section and Outlet Section of Orifice Meter. This drop in pressure can be measured using a differential pressure measuring instrument.

Since this differential pressure is in direct proportion to the flow-rate as per the Bernoulli’s Equation hence the differential pressure instrument can be configured to display flow-rate instead of showing differential pressure.

Working:

- The working principle of Orifice Meter is the same, as that of Venturi meter

- The orifice plate, is being fixed at a section of the pipe, creates an obstruction to the flow by providing an opening in the form of an orifice to the flow passage.

Orifice-meter-flow

Fig 1 Flow through an Orificemeter

- The area A0 of the orifice is much smaller than the cross-sectional area of the pipe. The flow from an upstream section, where it is uniform, adjusts itself in such a way that it contracts until a section downstream the orifice plate is reached, where the vena contracta is formed, and then expands to fill the passage of the pipe.

- One of the pressure tapings is usually provided at a distance of one diameter upstream the orifice plate where the flow is almost uniform (Sec. 1-1) and the other at a distance of half a diameter downstream the orifice plate.

- Vena-contracta is made at a distance of D/2 from orifice plate in downstream direction.

- Considering some assumptions as the fluid is ideal and the downstream pressure taping to be at the vena contracta (Sec. c-c), Now applying Bernoulli’s theorem in between Sec. 1-1 and Sec. c-c,

|

(1) |

where

and

are the piezometric pressures at Sec.1-1 and c-c respectively.

- From the equation of continuity,

|

(2) |

where Ac is the area of the vena contracta.

- With the help of Eq. (1), Eq. (2) One can write ;

|

Correction in Velocity

- As we know measured value of the piezometric pressure drop for a real fluid is always more due to friction than that assumed in case of an inviscid flow, a coefficient of velocity Cv (always less than 1) has to be introduced to determine the actual velocity Vc when the pressure drop in above velocity Eq. , is substituted by its measured value in terms of the manometer deflection ‘∆h’

|

(4) |

Hence, where ‘∆h’ is the difference in liquid levels in the manometer and ρm is the density of the manometric liquid.

Volumetric flow rate

|

(5) |

- If a coefficient of contraction Cc is defined as, Cc = Ac /A0, where A0 is the area of the orifice, then Eq.(5) can be written, with the help of Eq. (4),

where, Coefficient of discharge of orificemeter (Cd) is 0.61.

Orifice Plate

An Orifice Plate is inserted in between the Inlet and Outlet Sections to create a pressure drop and thus measure the flow.

Outlet Section

A linearly extending section similar to the Inlet section. Here also the diameter is the same as that of the outlet pipe for an end connection for an outgoing flow. Here we measure the Pressure of the media at this discharge.

As shown in the adjacent diagram, a gasket is used to seal the space between the Orifice Plate and the Flange surface, prevent leakage.

<< Click on image to enlarge

Sections 1 & 2 of the Orifice meter, are provided with an opening for attaching a differential pressure sensor (u-tube manometer, differential pressure indicator).

Material of construction:

The Orifice plates in the Orifice meter, in general, are made up of stainless steel of varying grades.

Shape & Size of Orifice meter:

Orifice meters are built in different forms depending upon the application specific requirement, The shape, size and location of holes on the Orifice Plate describes the Orifice Meter Specifications as per the following:

- Concentric Orifice Plate

- Eccentric Orifice Plate

- Segment Orifice Plate

- Quadrant Edge Orifice Plate

Concentric Orifice Plate

It is made up of SS and its thickness varies from 3.175 to 12.70 mm. The plate thickness at the orifice edge should not be exceeded by any of following parameters:

- 1 – D/50 where, D = The pipe inside diameter

- 2 – d/8 where, d = orifice bore diameter

- 3 – (D-d)/8

*Beta Ratio(β): It is the ratio of orifice bore diameter (d) to the pipe inside diameter (D).

Eccentric Orifice Plate

It is similar to Concentric Orifice plate other than the offset hole which is bored tangential to a circle, concentric with the pipe and of a diameter equal to 98% of that of the pipe. It is generally employed for measuring fluids containing

- Media having Solid particles

- Oils containing water

- Wet steam

Segment Orifice Plate

It has a hole which is a semi circle or a segment of circle. The diameter is customarily 98% of the diameter of the pipe.

Quadrant Edge Orifice Plate

This type of orifice plate is used for flow such as crude oil, high viscosity syrups or slurries etc. It is conceivably used when the line Reynolds Numbers* range from 100,000 or above or in between to 3,000 to 5,000 with a accuracy coefficient of roughly 0.5%.

Operation of Orifice meter:

- The fluid flows inside the Inlet section of the Orifice meter having a pressure P1.

- As the fluid proceeds further into the Converging section, its pressure reduces gradually and it finally reaches a value of P2 at the end of the Converging section and enter the Cylindrical section.

- The differential pressure sensor connected between the Inlet and the and the Cylindrical Throat section of the Orifice meter displays the difference in pressure (P1-P2). This difference in pressure is in direct proportion to the flow rate of the liquid flowing through the Orifice meter.

- Further the fluid passed through the Diverging recovery cone section and the velocity reduces thereby it regains its pressures. Designing a lesser angle of the Diverging recovery section, helps more in regaining the kinetic energy of the liquid.

Specifications of Orifice meter:

- Line Size: 6 mm to 800 mm

- Accuracy: +/-0.5% to +/-3.0%.

- Operating Temperature (Max.): Upto 800 degC

- Operating Pressure (Max.): Upto 400 bar

Applications of Orifice meter:

- Natural Gas

- Water Treatment Plants

- Oil Filtration Plants

- Petrochemicals and Refineries

Advantages of Orifice meter:

- The Orifice meter is very cheap as compared to other types of flow meters.

- Less space is required to Install and hence ideal for space constrained applications

- Operational response can be designed with perfection.

- Installation direction possibilities: Vertical / Horizontal / Inclined.

Limitations of Orifice meter:

- Easily gets clogged due to impurities in gas or in unclear liquids

- The minimum pressure that can be achieved for reading the flow is sometimes difficult to achieve due to limitations in the vena-contracta length for an Orifice Plate.

- Unlike Venturi meter, downstream pressure cannot be recovered in Orifice Meters. Overall head loss is around 40% to 90% of the differential pressure .

- Flow straighteners are required at the inlet and the outlet to attain streamline flow thereby increasing the cost and space for installation.

- Orifice Plate can get easily corroded with time thereby entails an error.

- Discharge Co-efficient obtained is low.