Types of Pressure Gauges

Pressure Gauge

Pressure gauge is the device which is used to measure the intensity of the fluid or pressure. Theoretically, pressure is measured in terms of amount of perpendicular force applied to per unit area of a surface. While, it is difficult and tedious in real situation to consider what reference point is being used to calculate the pressure with respect to force and area. Thus, researchers have invented and developed such gauges or devices which can measure pressure accurately and depending on the conditions. While selecting a pressure gauge, it is also important to consider which pressure type are we measuring? Whether is it absolute, differential, gauge, static or dynamic pressure? Thus, the gauge type may vary.

Aricle written By : Pallavi Wankhede

Types of Pressure Gauges:

Pressure gauge can be classified into hydrostatic, mechanical and electronics type gauges. These three main types are further classified as follows:

1. Hydrostatic Pressure Gauge:

This type of pressure gauge measures the pressure to the hydrostatic force per unit area at the base of a column of a fluid. Hydrostatic pressure gauges are designed for linear calibration. It also gives measurement irrespective of which gas is being used. While these pressure gauges are poor in dynamic response. Mercury column Manometer is a type of hydrostatic pressure gauge.

a. Liquid Column Gauge (Manometer) or Mercury column Manometer

In case of liquid column gauge, the column consists of liquid whose ends are exposed to different pressures. It works on the force applied due to gravity. The liquid in column will rise or fall until it’s in equilibrium with the pressure difference between the two ends of the tube where force is applied due to fluid pressure. A U-shaped tube half filled with liquid is a simple example of liquid column gauge or manometer where one side is connected to the region of interest or applied pressure (Pa) and other side as reference pressure also called as atmospheric pressure (P0). The difference between applied pressure and atmospheric pressure can be calculated in terms of pressure head and density of liquid as h*ρ*g (pressure head*density*acceleration due to gravity). It can be used for any fluid; however mercury is preferred due to its high density and low vapor pressure.

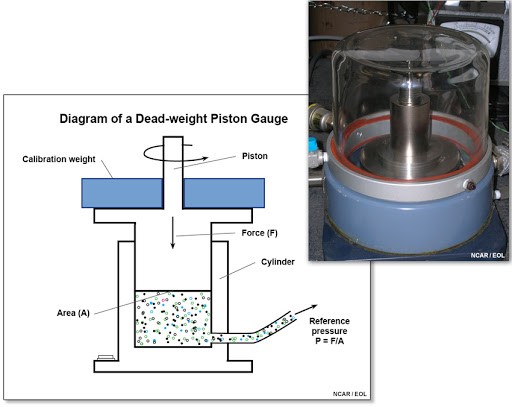

b. Piston

In case of piston gauge, the pressure measurement is directly connected to the movement of piston. This type is generally used in hydraulic applications where there is a need to give response with shock, vibration and sudden pressure change. Piston is connected to the secondary device to convert the signals into electric response.

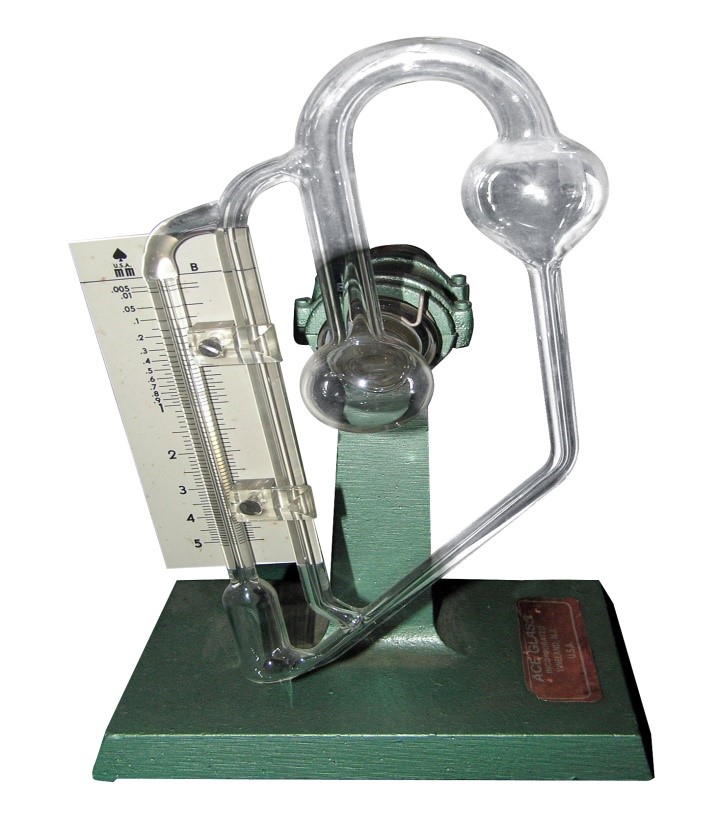

c. McLeod Gauge

This type of gauge isolates the gas and compresses it in a modified mercury manometer until, the pressure reaches to few millimeters of mercury. This technique is very slow and not preferable where continuous monitoring is needed, while it can give good accuracy. Its reading is dependent on the type of gas used as there is a compression mechanism. Thus, it ignores partial pressure from non-ideal gas or vapors like pump oils, mercury and even water (vapor) that compresses. Only, McLeod gauge measures the lowest direct pressure (0.1 MPa) with current technology and with respect to properties of the gas.

2. Mechanical/Aneroid Pressure Gauge:

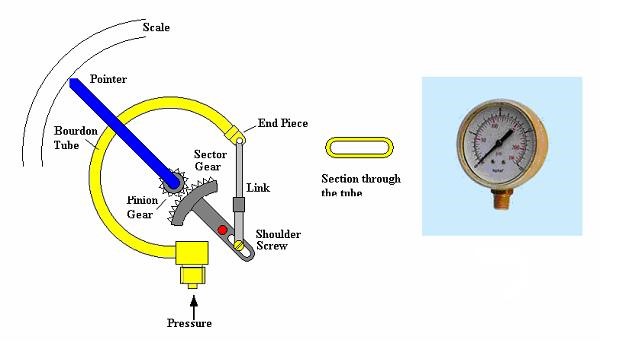

a. Bourdon Tube

Bourdon tube is a circular shaped tube having an oval cross section. It works on the principle that when there is a variation in internal and external pressure, the bent tube will change its shape due to expose. When the pressure is applied internally, the tube will start to straighten and returns to its original position after pressure is released. Depending on the tube material, bourdon tube has wide variety of applications. It is used in negative or positive pressure ranges. On the other hand, bourdon tubes are most widely used in process plant at industrial level. It gives direct pressure measurement with fast response and wide operating range. It is inexpensive and give good sensitivity, while can be sensitive to temperature and give hysteresis on cycling.

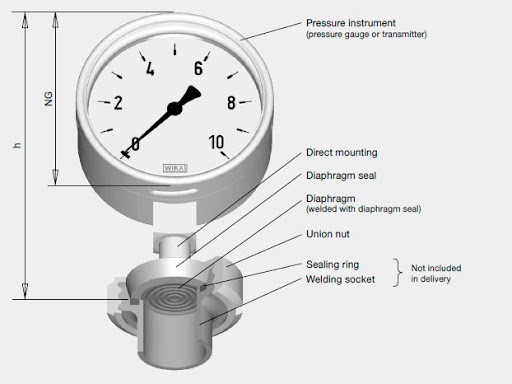

b. Diaphragm

Diaphragm is a flexible disc either in flat shape or concentric and made of metal with high tolerance. It can be used in measurement of pressure where deflection takes place. It is usually used for high pressure applications and to isolate the process fluid. It has proven and developed design which provides minimum friction, hysteresis and calibration problems. It is applicable where electrical transducer is used for pressure measurement.

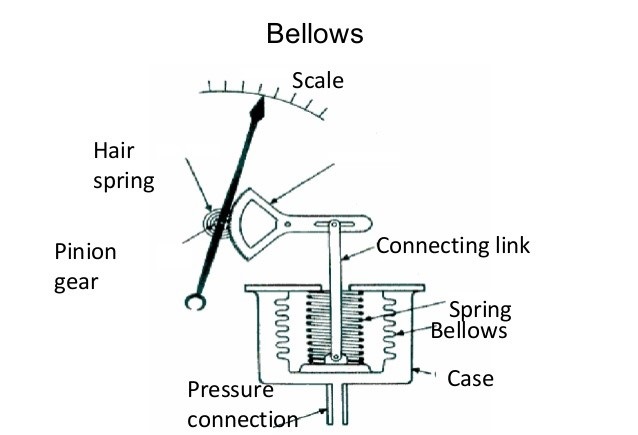

c. Bellows and Capsule

Bellows use the sealed chamber as a reference pressure and later driven by external pressure. Bellows is made of several capsules. The capsule usually consist two circular shaped, convoluted membrane (stainless steel) sealed tight around the circumference, while the membrane is attached at one end to the source and the other end to an indicating instrument. It is used to sense small pressure as well as small pressure difference or small pressure requires that as an absolute pressure. It is used in sensitive part of aircraft such as air speed indicators, rate of climb indicators and in processing equipment like cryogenic vessels.

3. Electronic Pressure Gauge:

a. Thermal conductivity

In this type of gauge, a wire filament is heated by running current through it. As a gas increases in density, it can increase in pressure and ability to conduct heat. In this gauge, a thermocouple or RTD is used to measure the temperature of the filament. This temperature is dependent on the rate at which gas loses heat to the surrounding gas. The chemical composition of gas is very sensitive while calibrating temperature and so as pressure.

b. Ionization Gauge

It measures pressure indirectly by sensing the number of electrical ions produced when the gas is bombarded with electrons. It is most sensitive gauges for very low pressure especially in the conditions like high vacuum.

Content Source:

https://www.precisionmass.com/; https://en.wikipedia.org/;

Image Source:

https://www.indiamart.com/; https://www.instrumentationtoolbox.com/; https://commons.wikimedia.org/; http://sabadejlah.com/; https://en.wikipedia.org/