OXYGEN GENERATION TECHNIQUE

In this article we talk about how effectively oxygen can be generated using PSA (Pressure Swing Adsorption) technique from Natural Air / Raw Air.

As we all now the natural air contains 21% Oxygen, 78% Nitrogen, 0.9% Argon (Inert Gas) and 0.1% other traces of gases. Our purpose is to separate this 21% Oxygen from the remaining gaseous components mainly from Nitrogen (78%) present in Air.

There is three common techniques to generate oxygen

- Cryogenic Separation

- Pressure Swing Adsorption

- Membrane Technology

Here we talk about PSA (Pressure swing adsorption) technique.

Pressure swing adsorption (PSA) is a technology that is used to separate a desired gaseous component (Oxygen) from a mixture of gases/Air by applying external pressure, using highly selective adsorbent / molecular sieve. The molecular characteristics and affinity of various gaseous components are different towards the adsorbent material. Specific adsorbent materials like activated carbon, zeolites, molecular sieves etc., are used as traps for adsorbing the main gaseous species (Nitrogen-78%) at high pressure. The whole process usually operates at ambient temperatures. After this step, the entire process swings or regenerated back by creating low pressure in the adsorbing bed to desorb the adsorbed material (Nitrogen) and released to Atmosphere. As a result the produced oxygen concentration 93% and above.

Pressure swing adsorption processes work on the principle that gases attracted to solid surfaces or technically put – “adsorbed under high pressure.” As the pressure keeps on increasing, more and more gases tend to get adsorbed. When the working pressure is lowered, the gases are desorbed or released. PSA processes are usually used to separate gases that we want, like Oxygen in this case, from a mixture of different gases because they tend to be attracted to different solid surfaces more or less strongly.

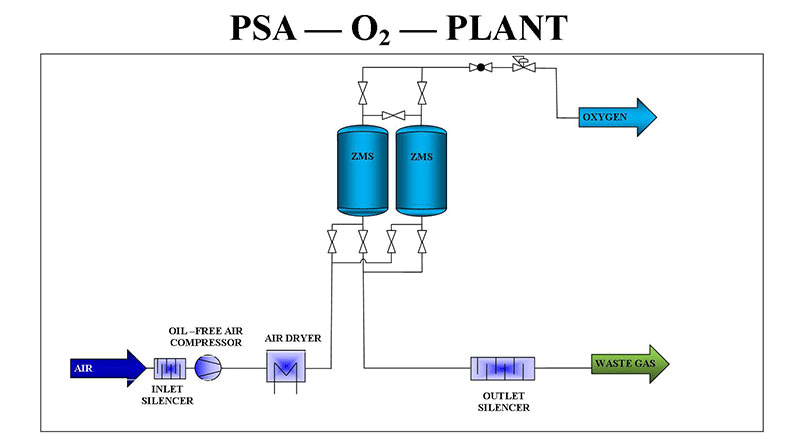

Oxygen generation plants based on PSA techniques usually comprised of following units.

- Compressor

- Air Dryer

- Air Filtration Unit

- Storage Vessel

- Vessels Packed with adsorbing Material

- Oxygen Storage Vessel.

Note : Zeolite is used as adsorbent or say for trapping Nitrogen Components.

- Here, the ambient air or natural air acts as raw material for the whole process. Air gets sucked using compressor and is compressed first.

- Now Compressed air passes through Air filter, followed by dryer to remove moisture content, if any and then stored at high pressure into the Air storage Vessel.

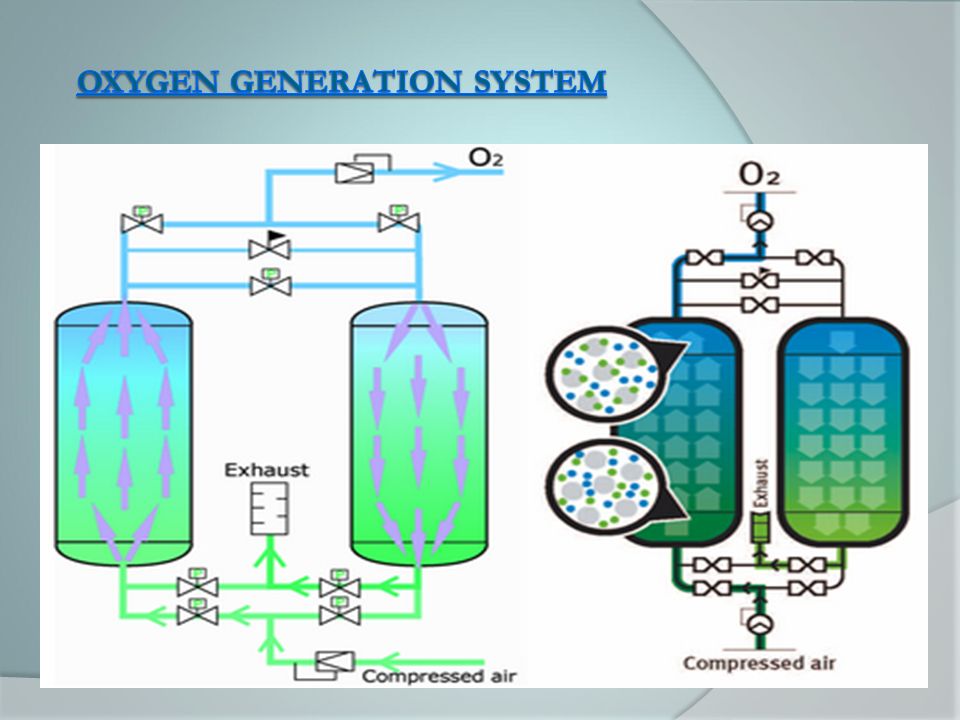

- This high pressure Air passes through the zeolite bed where Nitrogen mainly gets adsorbed in the pores of zeolite.

- After the Nitrogen is adsorbed the remaining oxygen molecules comes out of the vessel having 93% concentration and more.

- As the adsorber (zeolite) got saturated with Nitrogen gas its time to regenerate the adsorbing bed so that oxygen purity remains intact.

- For regeneration of adsorbing bed a negative pressure is created into the bed so that the trapped nitrogen molecules desorbed and again ready for the adsorption.

- Since After adsorption, regeneration of bed is required hence in industry to make this process continuous two minimum packed vessels is used. In One vessel adsorption going on where as in another vessel desorption takes place which keeps on swinging. That’s why we call it pressure swing technique. An automatic and pneumatic vessels balance system ensures a continuous oxygen flow.

These plants have quite enough capacities to generate Oxygen. Since the purity of oxygen is very much high so one can use it for medical grade too. Right now this technique is frequently getting used to absorbs Nitrogen from the air and generate medical Oxygen for the covid-19 patients at the hospitals. One can directly supply this medical grade oxygen to the hospitals via pipelines. Thus Oxygen generated is use to fill oxygen cylinders, oxygen tankers too.

Note : The Oxygen generated by these plants is less pure than liquid Oxygen derived from cryogenic technology.

ImageSource : Direct Industry; GENERON; SlidePlayer